Battery Tech Article

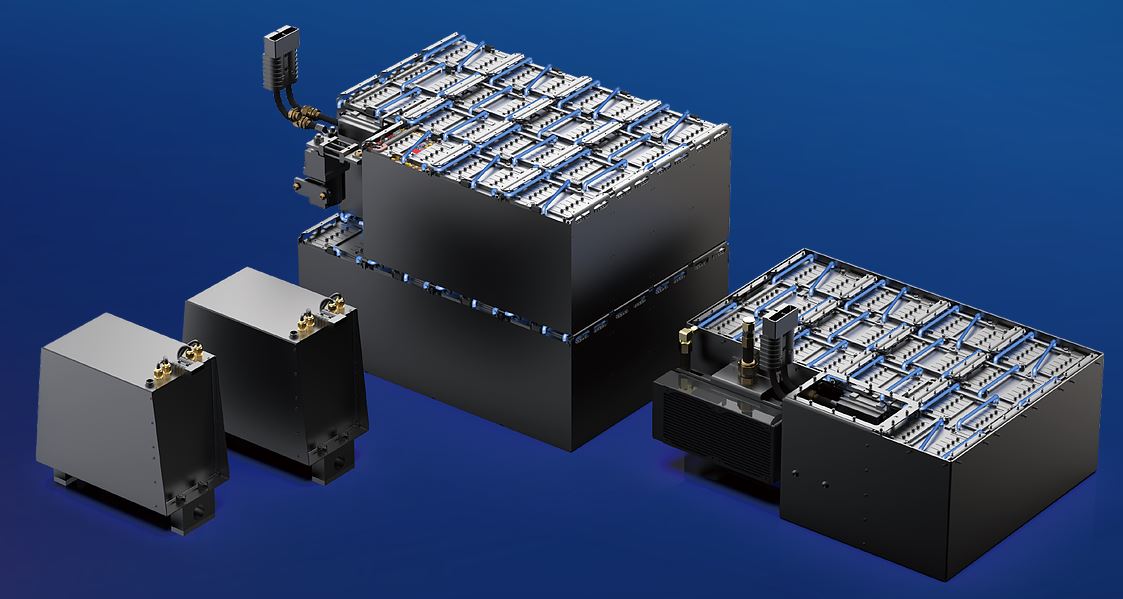

High Power Batteries and Thermal Management Solution

Technology Overview

The proposed heat management technology focuses on high power applications (above 2C) that result in battery overheating, which can cause significant reduction in lifetime, performance and safety hazards.Thermal Management System (TMS) - During normal operation of batteries, the battery cells emit heat, which could cause the temperature of the battery pack to rise drastically. Without a TMS in place, heat would be trapped in the battery pack and could cause cell-degradation, leading to shortened lifetime, decreased performance and fire hazard. The proposed thermal management solution overcomes battery-overheating issue. The solution consists of liquid cooling and a proprietary material that could effectively prevent fire propagation, extend lifetime and increase performance of the battery. Working Mechanism of TMS - The TMS works by dissipating heat away from the battery cells. The proprietary thermal material is dielectric and can be poured directly into any battery pack. As the material flows into the pack, the material envelops the cells and serves as a protective layer between the cells. The material solidifies when it cools. During battery operation, the material absorbs heat emitted by the battery cells. Heat is then dissipated from the material via a liquid cooling circuit integrated in the TMS.The technology provider is actively seeking potential partnerships and technology licensing for its (i) proprietary TMS and (ii) standard battery module that consist of the TMS. The technology provider is also open to working with potential partners to fast-track their Second Generation phase change material (PCM) development.

Technology Features & Specifications

Battery Module Specification Specification Value Unit Energy 1.15 kWh Cell Type NMC Pouch - Type A B C D E F - Configuration 12S1P 6S2P 4S3P 3S4P 2S6P 1S12P - Nominal Voltage 44.4 22.2 14.8 11.1 7.4 3.7 V Current Capacity 26 52 78 104 156 312 Ah Max Discharge Current 155 312 312 312 312 312 A Peak Discharge Current 355 (2s) 355 (2s) 355 (2s) 355 (2s) 355 (2s) 355 (2s) A Max Charge Current 52 104 156 208 312 312 A Peak Charge Current 215 (2s) 355 (2s) 355 (2s) 355 (2s) 355 (2s) 355 (2s) A Weight 9 kg Specific Gravimetric Density 128 Wh/kg Specific Volumetric Density 241 Wh/L Specific Power Density 1751 W/kg Cycle Life to 70% SOC 2800 cycles (-2C/1C); 4000 cycles (-1C/1C) cycles Storage Temperature -40 to 60 °C Operation Temperature -30 to 55 °C Waterproof Rating IP67 Cooling Method Liquid and Phase Change Material Phase Change Material Specification Specification PCM-3 Units Details Melting Point 45 °C Melting Range 45 - 50 °C Density 834 kg/m3 Room Temperature Thermal Expansion – Solid Phase 0.074 %/°C Measured from room temperature to melting onset Thermal Expansion During Melting 0.051 %/°C Measured after melting to 75°C Thermal Conductivity 2.85 W/m-k Latent Heat 210 J/g Specific Heat 252 J/g-k Specific Heat Solid Electrical Resistance 0.33 10^6 Ωm Thermal Cycle Lifetime >10,000 # of melting cycles

Potential Applications

The proposed technology caters to a wide variety of applications in material handling, urban mobility, renewable energy sectors and second-life usage. Material Handling - The material handling applications consist of construction, industrial and agricultural vehicles. These applications are looking for revolutionary methods to decrease their carbon footprint and increase their operational efficiency, while lowering their total costs of ownership. Many companies are moving towards adoption of electric models of their vehicles, or converting their existing Internal Combustion Engine (ICE) vehicles to electric. However, battery-overheating problem is rampant in these applications due to its high power usage, and vehicle operators tend to compromise with a lower-performance vehicle due to battery limitations. Rovilus’ technology could resolve this problem by enhancing performance, meeting safety requirements and increasing lifetime (and thereby lowering total costs of ownership). Urban Mobility - Most countries have adopted legislations and policies to move towards electrification of commercial fleets and passenger vehicles. As companies are in the race to develop cheaper and safer batteries with longer-range, there remain other problems to be addressed especially for applications that will be used in tropical climates (i.e. Singapore) and cold climates (i.e. Sweden). The TMS is able to provide high performance batteries under those climates, while ensuring lifetime and safety. Energy Storage Systems - The TMS has been used in high power energy storage systems to manage battery-overheating issues. It has also been tested to work on low quality batteries (including second-life batteries), and is useful for ensuring safety and providing life extension benefits in energy storage systems.

Market Trends Opportunities

The current applications include specialty vehicles and energy storage systems, and the total available market size is approximately US$201B.

Benefits

Safety Feature - The TMS can effectively prevent fire propagation in the event of a thermal runaway. For the battery packs, there are also multi-level safety systems in place, coupled with smart Battery Management Systems, to prevent any potential battery failure.Reduced Total Costs of Ownership - With a market-leading lifetime of 4,000 cycles for most applications, the solution reduces total costs of ownership by allowing customers to use the same battery pack for 3X longer.15-Minute Fast Charging & Continuous Operation - The battery packs enable opportunity fast charging and allow vehicle owners to operate continuously with minimal downtime. With the technology provider's fast charging technology, vehicle operators are able to enjoy fast charging of 15 minutes, and increase in operational efficiency. Wide Range of Operating Temperature - The TMS operates effectively in -40 to 60 degrees Celsius, allowing customers to adopt electric models of its application where it may be previously impossible to do so. Customizable Design - The battery packs are designed in a modular format to accommodate various applications that come in different shapes and sizes. This significantly reduces customization costs while allowing flexibility in the design of the pack, enabling our customers to have a tailored power pack that meets their requirements and timeline.

Key information

Technology Category- Energy - Battery & SuperCapacitor

ID Number: TO134655

Source: IPI Singapore