Battery Tech Article

Battery Management System to Refurbish Lithium-ion Batteries

Technology Overview

Recycling or refurbishing of lithium-ion batteries is crucial in tackling the challenges of climate change and air pollution. While there is the demand for batteries to have more capacity and longer life cycles, lots of time and investment are also required to dismantle and recycle batteries. Precious metal, such as Lithium, needs to be saved while batteries need to be renewable as well.A start-up company has developed a Battery Management System (BMS) circuit, software and process to refurbish small lithium-ion batteries used in wheelchairs, laptops, tablets, drones and more. The technology enables the consumer to achieve significant cost savings and environmental benefits compared to buying new batteries or using other battery recycling methods, with a wide support for different types of batteries from various battery manufacturers. The company is seeking potential partners in Singapore to collaborate through a licensing agreement, whereby the know-how and the process of battery refurbishing will be transferred to the partner.

Technology Features & Specifications

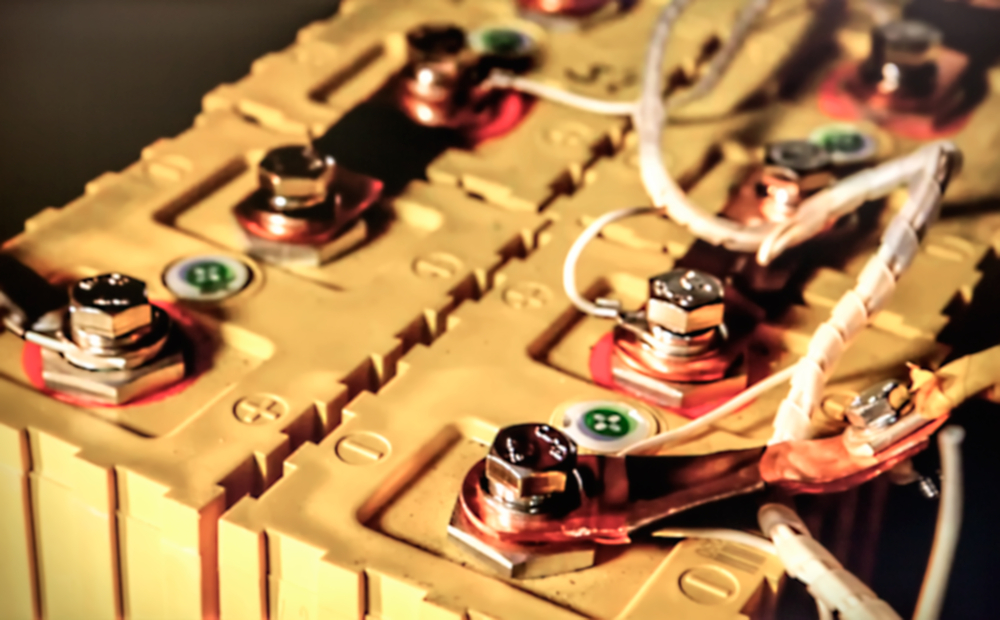

The technology provider is the proprietary owner of a BMS circuit, software and process. The new BMS CPU is interfaced with the existing BMS to control the normal charging / discharging operations. It is capable to access battery health information from the existing battery BMS, and recalibrate the full charge capacity for each cells in the refurbished battery pack, so that it can deliver the correct rated power. The full charge capacity is an estimate of the battery's state of health (SOH) based on proprietary software loaded in the BMS CPU. The technology provider and their partner have worked with more than 3000 types of BMS / batteries to date. The battery refurbishing process consists of the following steps: Dismantle old battery packs Test cells for state of health, internal resistance, self-discharge, voltage, current, etc Replace degraded cells (<50% SOH) with new cells Repack batteries in existing casing with BMS circuit Recalibrate full charge capacity data Refurbished batteries are estimated to be up to 30% cheaper than buying new batteries.

Potential Applications

The battery recycling and refreshing technology is applicable for small and micro e-mobility devices such as wheelchairs, e-bikes and e-scooters, electric devices, robots, laptops, tablets, power tools, drones and more manufactured by Japanese and South Korean companies.

Market Trends Opportunities

Demand for battery refresh or recycling continues to increase significantly. According to a report by Reports and Data (US) in 2019, the world market cap for all battery recycling is 4B USD in 2019. The market for this technology's targets is 1B USD, which is estimated to be 4B USD in 2026. The current target market is battery refreshing for smaller e-mobility (drones, e-scooters, e-bikes, wheelchairs), electric devices (tools, PC), robots, and more with plans to apply Machine Learning and IoT in the know-how in the long term to make the technology more efficient and scalable.

Benefits

The benefits of the technology include: Special know-how to unlock BMS data and readjust the full charge capacity data More than 30% cheaper than buying new batteries Batteries may be refurbished with warranty even after original battery manufacturers finish their support Batteries may be refurbished as many times as the original BMS can be reused Save precious metals and reduce greenhouse gases

Key information

Technology Category- Energy - Battery & SuperCapacitor

- Waste Management & Recycling - Waste-to-Energy

ID Number: TO156160

Source: IPI Singapore